From this FArs News tweet:

Iran Started Injecting Gas into Next-Generation Centrifuges at Natanz Nuclear Facility in A Ceremony Attended by President Hassan Rouhani Through Videoconferencing

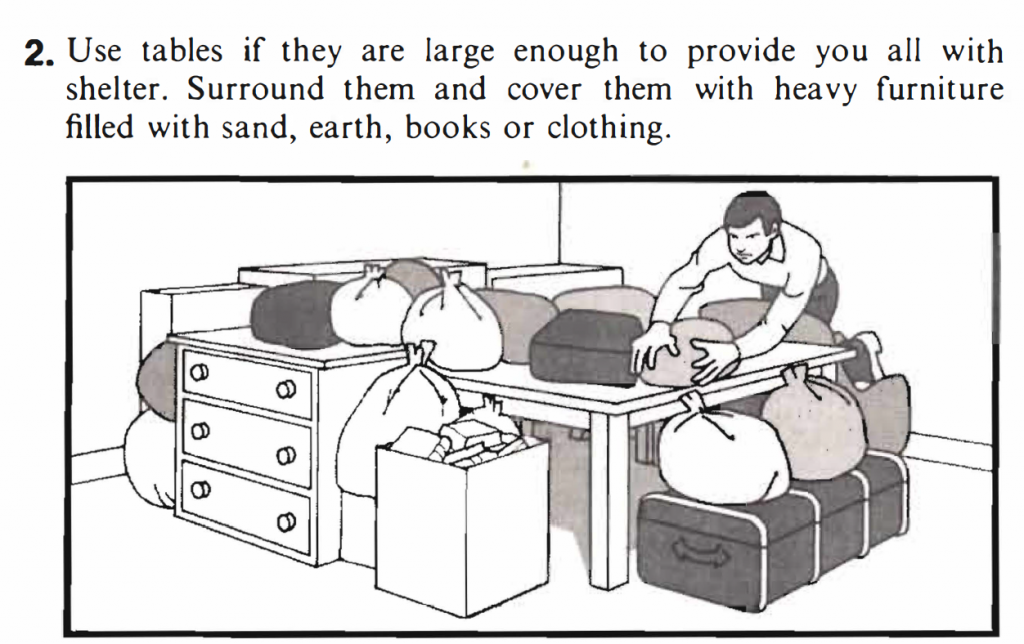

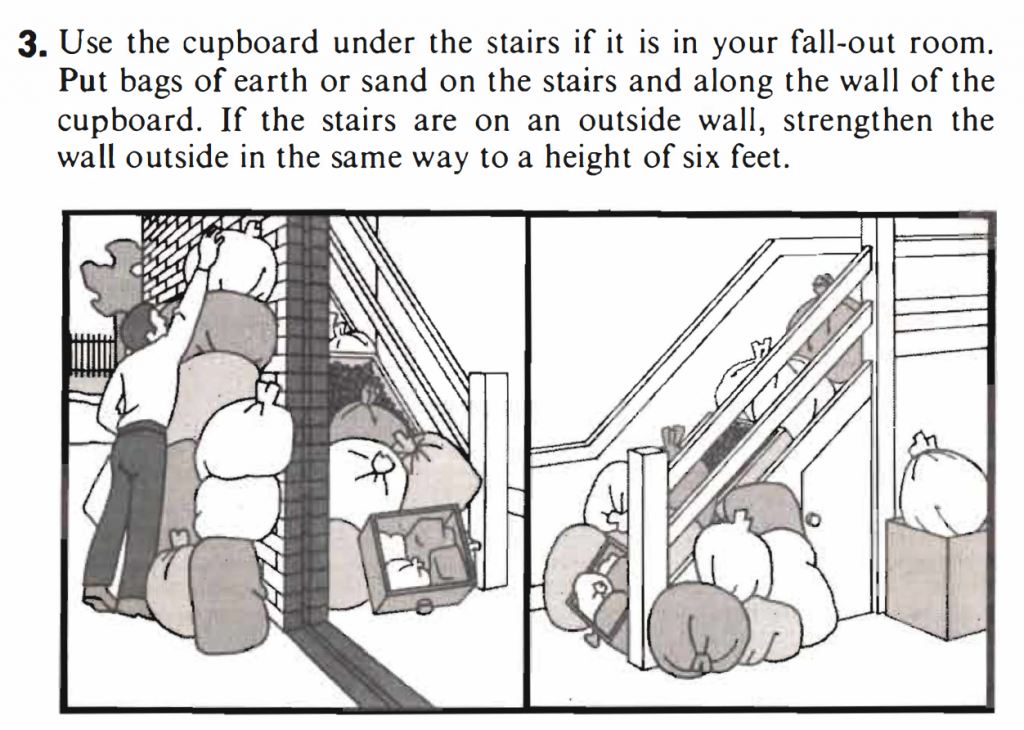

I lack the confidence to ID the precise centrifuges, but the tweet includes this photo: